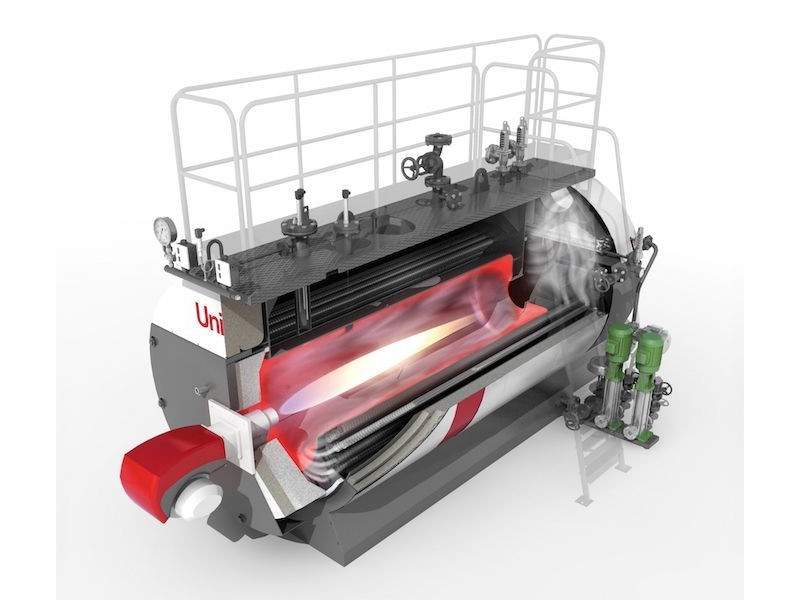

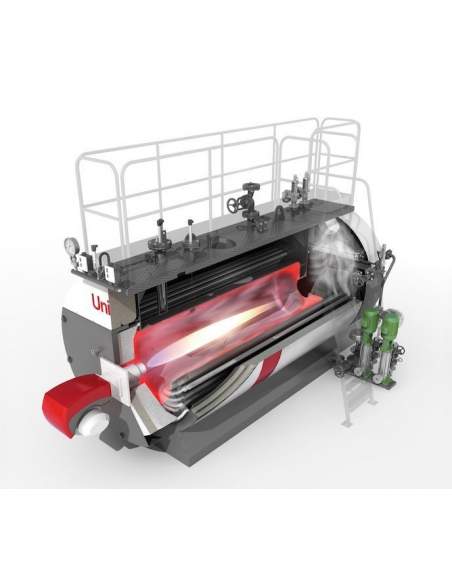

High pressure steam boiler, three pass reversed flame, smooth pipes with turbulators, 90% efficiency

BAHR’12 is a family of packaged smoke tube steam boilers, three pass reversed flame, wet back. Standard safety pressure up to 15 bar and output from 300 to 6000 kg/h. It can be operated with liquid or gaseous fuels. Every model is complete with regulations and safety accessories for automatic operation and easy commissioning.

In compliance to the current laws, each steam boiler undergoes a conformity assessment, carried out by a Notified Body. The conformance to the essential safety requirements demanded by the European Pressure Equipment Directive 97/23/CE (PED) is guaranteed by the CE mark.

Design features: By means of the reverse flame principle the smoke gases in the combustion chamber are diverted to the front, then reversed again to the smoke tube sections and discharged through the chimney connection. The appliance is designed to ensure low heating loads in the combustion chamber and low superficial loads.

Boiler body: is made up of a cylindrical shell and a wet back furnace, made of high quality P265GH EN 10028-2 steel. All the materials have certificates attesting their chemical and mechanical characteristics, the controls are carried out during each production stage, and, theirs suitability for use as well. The welding seams are carried out with electric arc by qualified personnel in compliance to certified procedures and are subjected to Non Destructive Tests, in accordance to an internal “Manufacturing and Control” program. Once the boilers have been manufactured they are subjected to hydraulic testing in accordance to the requirement 7.4 – Annex I, laid down in the Directive 97/23/CE (PED).

Smoke tubes: made of high quality P235GH EN 10217/2 steel, are welded to tube plates. Pipes are equipped with helical turbulators.

Front door: is built in welded steel plate, completely cladded internally with a layer of insulation material and with a layer of high density refractory material. The door is fitted with hinges which enable it to be easily adjusted and quickly opened. Moreover, the door is fitted with a self-cleaning sight glass for combustion control during boiler operation.

Rear smoke-box: is built in welded steel plate and fixed on to the tube plate by nuts for an easy access to it. It is fitted with a small door for cleaning purposes and an horizontal flue connection, with a diameter sized to the boiler’s output.

The rear smoke-box is pre-arranged for the installation of an integral economizer.

The base: is built with a steel frame, welded to the tube plates and closed with steel plates.

Walkway: positioned on the top part of the boiler, is made of steel, covered with chequered plate and completed; on request with handrail and access ladder.

Insulation: the shell is thermally insulated with a 100 mm rock wool cladding binded with high density, thick thermosetting resins, suitably supported and covered externally in 10/10 thick enamelled aluminum. The frontal parts of the boiler