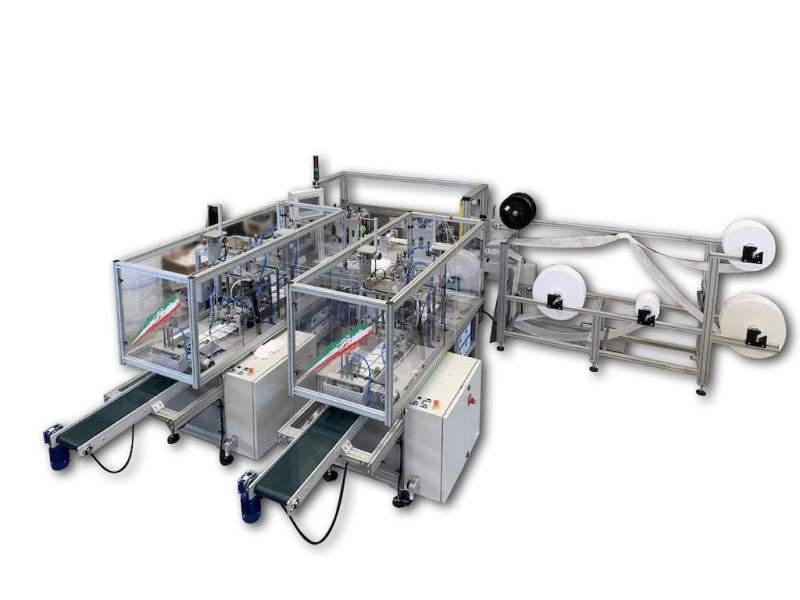

TEXMA T-MASK2

100% Made in Italy

Automatic machine / plant for the production of surgical masks

Double throughtput for production of 100 masks per minute

Product Process:

Automatically align and feed the three rolls of material, for Upper layer, filtering layer and bottom layer. Double side continuous Ultrasonic blank pressing, after continuous wheel blank pressing and cutting, separately transfer to two working stations for ear belts welding, automatically count and cast up after welding, highly improve the Production efficiency.

Technology Characteristics:

1. One Production Line Installed With Two Welding Stations, Semi-Finished Materials Automatically Be Transferred To Two Working Stations For Ear Belts Welding Process.

2. Ear Belts Automatically Cutting And Welding By Ultrasonic Technology.

3. Nose Clip Can Automatically Feeding,Cutting And Ultrasonic Welding

Composed by:

• Feeding area Three cloth rolls, each with 2 non-woven rolls and 1 filter paper roll. A reel for the bridge of the nose.

• Mask body welding area. The mask body is welded on both sides (lengthwise), using ultrasonic welding, two rollers are continuous welding.

The nose bridge is conveyed at the same time as welding on both sides. After welding on both sides in the length direction, perform intermediate welding in the width direction and cut into one , The size of each mask.

• Transmission area. Store the welding piece in pieces and transfer it to the two ear band welding stations.

• Earband processing area. Two ear band welding machines (meaning "one-to-two"). Equipped with two ear band welding machines, ear band welding included, ear band requirements-ear band cutting-ear band welding.

Technical details:

• Mask Type SURGICAL MEDICAL MASK.

• Specification 175mmx95mm

• Speed 100pcs/Min

• Material PP Nonwoven Composite Fiber

• Processing Mode Automatic Welding

• Operation Screen Touch Screen

• Air pressure 0.6MPa

• Power 10KW

• Voltage 220V/50HZ

• Area 5000mm*6000mm*1800mm