List of products by brand SETEX

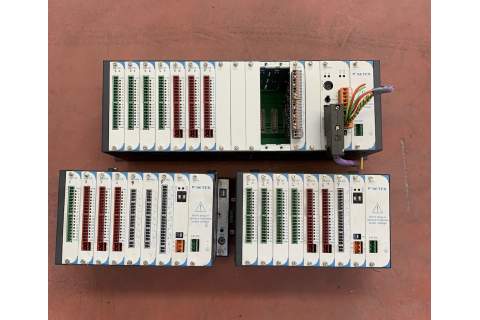

SECOM Controller Universally applicable solutions for tomorrows textile dyeing and finishing Many textile machine manufacturers around the world are finding their ways to reduce carbon emission and the use of energy. The complexity in textile production is growing constantly. SECOM controls are adding accessibility and efficiency into this workflow. Simply advanced The entire family of SECOM Windows CE controls is built on state-of-the-art technology and provides innovative tools for daily production. RFID extensions as smart login for a managed machine use, a clearly structured process visualization and customized information possibilities for e.g. next operator call are some important features out of the portfolio. Universally applicable solutions Considering the complexity of yarn, fabric and other kind of dye machines, the high degree of parallel processing of SECOM controls provides endless process possibilities. The combination with the modular SETEX PLC concept allows a performance and cost effective adaptation to all kind of dye machines. Many textile machinery makers worldwide use these utilities for a new crop of opportunities. Communicative The key to success in improving operational efficiency leads to streamline the workflow. For continuously optimizing production processes with minimize risk there’s no way around integration with OrgaTEX.MES software. All SECOM CE controls have built in standard Ethernet network functionality. Effective integration SECOM controls take care that your automatic dye kitchens and dosing systems work precisely in sync with machine calls. The logistics for charge-tanks and preparation-tanks provides features for “batch overlapping” dye lot preparation with “look-ahead” functions. The entire production data acquisition and collecting, even values (e.g. pH) entered directly on the controller, are provided to MES, ERP and “Energy Management” systems for up-to-the-minute information for immediate actions. Intelligent flow Fabric, machine and product correlations are used by the integrated formula management to calculate the optimal dyeing contacts, the best rinsing type, water temperature and quantity. Using our innovative functions helps to keep the number of program steps slim but powerful. Advanced features as conductivity, article carry over and critical step lights can easily be added on top of the standard functionality. Multilingual Various languages and fonts can simply be switched on, e.g. chinese, vietnamese, cyrillic …. Durable and robust Development and selection of components based on characteristics like extended temperature ranges, rugged environments, unstable power supply and corrosive conditions. Safe and protected Unforeseen incidents as electrical power failure may happen frequently. The new SECOM controls have functions for auto-sync, UPS and snapshot recovery. Instead of downtimes you can proceed with your production exactly where it stopped right before the power failure without any loss of data and time. The USB port connects external devices as backup, barcode and RFID reader. Professional internet service The more complex a technology, the more perfect and flexible its service has to be. SECOM CE -controls provide internet remote access possibilities with individual customized security gateways and saving of service-expenses. If desired a 24/7 professional support availability serves to minimize down-times.