Satin

Satin fabric is fine, shiny, smooth, soft at touch. Made with satin weave, in which weave points are widely distributed so as to be hidden. Its best material is silk, but it can also be made with artificial fibers such as rayon or synthetic fibers such as polyester; whereas, if it is made of cotton, it must undergo a finishing calendering to get a shiny look.

Hemp

Linen is a fiber made from cellulose by almost 70%. Like all bast fibers, linen has an average elementary fiber length ranging from 20 to 30 mm., its width is approximately 20 to 30 microns and the fiber has a polygonal section. The fiber has a shiny appearance and a cool and slippery hand. In case of moisture this fiber absorbs water swelling moderately; if burned, it produces a fine black-gray powder, as it is made from cellulose.

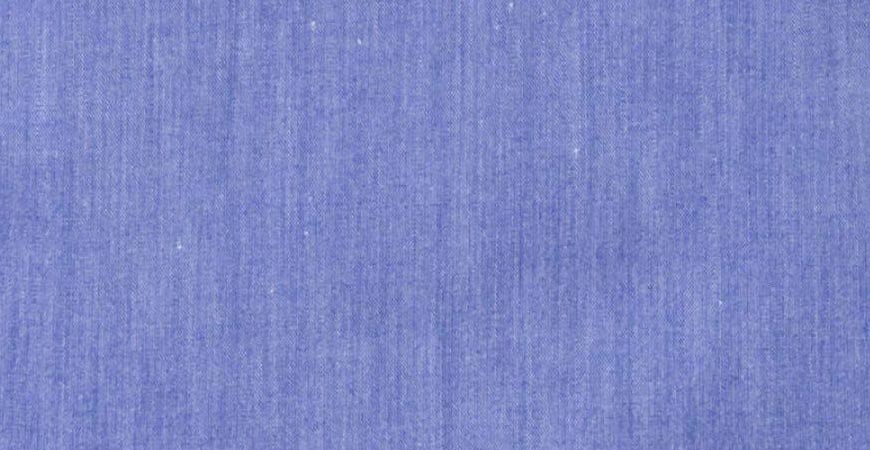

Denim

Denim is the most used fabric to manufacture jeans trousers. The most popular color is the non-regular blue, like that in the picture, although there is a lot of production also in other colors. Finishing treatments can change the appearance of the fabric as in stonewashed or faded. It is also used for shirts, vests, jackets, regarding the "juvenile" or casual clothing, but also for classic items. In ancient times it was made of a linen warp and a cotton weft, whereas nowadays it is entirely made of cotton. Its features are robustness and strength (of the material used) together with a certain adaptability (of the twill weave). Denim is very similar to fustian, which is its ancestor. The difference between them is the color of the warp: warp and weft of the fustian are the same color, whereas in denim the weft texture is white or off-white and the warp is blue. [Source: Wikipedia]

Fleece Cotton

Fabric derived from wefting that develops through the insertion of additional thread, usually a thick one, that does not form knits but binds to the base fabric by inserting with a loop on a needle and as a floating thread on the other needles according to the ratio. The particular structure of this product makes it suitable for raising either in tubular or open, and before or after dyeing. In order to obtain correct dimensional stability copper coating is fundamental and it must be done by fully vaporising and over-feeding, and by compacting with rubber belt in order to recover tensions and make the item suitable for manufacturing tracksuits. An alternative to manufacture technical items, which require greater performances, is the use of synthetic fibers together with cotton blend or thread, which allows the thermo-setting of the synthetic part by increasing the final stability, or to obtain stability and elasticity as for mixed items made of both cotton and Lycra.

Lining

Lining is a coating fabric which can be applied both on the inside of a piece of clothing, for example, and on the outside, as in a mattress. It is fundamental to manufacture dresses, jackets, coats, pants, skirts. The material used varies according to features: silk, cupro, polyester, polyamide, viscose, and acetate satin weave if it has to glide; wool, and fleece cotton if it has to give a warmth feeling; polyester, cotton, combed wool and related blends for a decorative effect.

Interlock cotton

Knitted fabric obtained by two sets of needles alternately working on the two bars. This item, which is also intended for the manufacturing of clothes and underwear, undergoes a processing cycle similar to Jersey items. Due to its particular shaved surface on both sides, it is mainly used in the manufacturing of pajamas, in which case it is used raised (fleece) on the inside to give greater softness and warmth. In order to recover all tensions built up during the raising and/or grinding, correct height and over-feeding during copper coating is fundamental, as well as a subsequent compaction by Sanfor machines with rubber belt, more suitable to compress knits and to recover stability and weight per square meter, also improving the hand.

Jersey cotton

Knitted fabric originally made by the fishermen of the English island of the same name: interlacing of a single thread horizontally and vertically to make a single jersey. Its typical elasticity makes it suitable for different uses such as menswear and womenswear, underwear, technical sports and industrial clothes. according to its strructure and use for which it is intended, the main processes, in addition to dyeing, are finishing and some important pre- dyeing treatments. The most common are mercerizing and singeing. Sanforizing is the most important final operation, which is also required after grinding in order to give Jersey items dimensional stability, uniform appearance and hand. It works with compactors equipped with rubber belt (Sanfor) for items in Viscose, Cotton and blends. This treatment ennobles the material, giving a silky hand, smooth surface and reducing the washing.

Wool

Wool is the most important and widespread animal fiber derived from sheep and ram fleece through spring shearing (sometimes twice a year) of livestock. Wool can be easily dyed with differente dyestuff: acids, premetalised, chrome, vat, reactive etc... The main purposes include clothes, knits, alone or mixed with other fibers, technical purposes (filters etc.), blankets, carpets, felts, etc. Among the main processes which use flat wool fabrics for clothing purposes there are preparation treatments such as: carbonising, treatment with sulfuric acid for the removal of fibers and plant waste, fulling, wet treatment for controlled felting, treatments with Angra , mainly sulfur-based. Whereas the main finishing treatments after dyeing range from fulling in dry with specific auxiliary softeners to shearing, singeing, decatising and final compaction with Sanfor machines with rubber belt, which determine the hand and the final look.

Piqué cotton

It belongs to lined fabrics. Due to the interlace, it is normally made by two chains, an interlace warp and a filling warp. With one tight chain and and a loose one during the process we obtain the piqué effect. Hot item for the manufacturing of men's clothing called "Polo" made with the typical collar made on flat knitting machines that suits different uses. It can be yarn-dyed, piece-dyed, mercerized, etc. in combination to collars for sportswear and casual clothing, with special line effects for navy clothing. The manufacturing process reflects classic processes, from mercerization, dyeing, and finishing with effective compaction performed with Sanfor machines with rubber belt and cylinder steaming at the entrance. Piqué fabric is often combined with elastomeric threads (Lycra) in order to increase elasticity and catch, or with polyester threads to increase strength if aimed at extreme sports or technical/industrial use.

Polyester

Polyesters are a type of polymers obtained by step polymerization via condensation that contain the functional group of esters along the main carbon chain. Polyester yarns are used in clothing (especially sports), furniture (curtains, floors, coated lining furniture). In order to match functional features to a greater comfort when in contact with skin,they are often blended with natural fibers such as, in particular, cotton. Their main use is, however, for technical textiles (transport, geotextiles, medical, safety devices...). [Source: Wikipedia]

Poplin

Poplin is a thin cotton fabric with cool and dry hand, it is shiny, compact but soft. Nowadays it is a very compact and durable fabric although fine, light, made of different yarns, cotton, silk and man-made fibers, often in blends. Yarns are extremely thin, twisted, mercerized, and result in a fresh tissue, for lack of hair, and smooth. Poplin is suitable for clothes and linen and it is the main fabric for the manufacturing of men's shirts. It used to be only white, then pastel color and, in order to satisfy fashion needs, it is now produced also in bright colors.

Rib cotton

Some of the simplest and least requested fabrics on the market, but suitable for the manufacturing of both men and womenswear. The classic rib is 1:1 in which straight and reverse are identical in the recurrence of the weave, but there can be a different ratio and be called after it: rib 2:2, 2:1 and so on. The manufacturing process is similar to that of other knitted items and can be finished in tubular felt compactor or open-loop on rubber belt compactor, Sanfor, wheich gives the best results. Rarely mercerized or raised, often combined with elastomeric yarns for the manufacturing of medical articles or inserts and wrists of different materials.

Silk

Silk, nowadays almost exclusively made in East Asian countries and China (though very much manufactured in the Como area), is a silky filament yarn spun by silkworms and it consists of two protein substances: fibroin and sericin and by 2-3% of fat and waxy materials, dyestuff and minerals. Silk is produced by silkworms, which secrete a long double and continuous filament (burr) that wraps around itself, forming the cocoon that is dipped in hot water to separate leaders and unravel it. In the spinning, the cocoon will join two or more filaments, the yarn thus obtained is twisted and put on the reel: this way we get raw silk. It can be white, yellowish, greenish or reddish. The dyeability of silk is similar to that of wool: it is dyed with basic dyestuff, acids, directs, premetallised dyes, vat dyes. The knitted fabrics of silk and those mixed with viscose and/or cotton are manufactured with circular machines, and they are usually finished with chemicals determined by purpose and use. Generally there are combinations of finishing based on silicone emulsions and resins to enhance stability, resistance to use and final appearance, etc. To complete these treatments there are mechanical finishing processes such as Sanfor rubber belt with slight compression.

Velvet

Velvet is a type of fabric that has either thick hair (joined or cut velvet) on the right face, or a series of tiny loops of wire. It is made in the frame with very thin yarns using two warps, one of which for the base (warp coarse) and one for the hair (warp hair), and a single plot. The velvet frame must be provided with two beams, one for the warp coarse and one for the hair warp that should be much higher in length than the other because hair wires must go a long way to go around to the irons. There are wool and silk velvet fabrics, though cotton is the most common when we are referring to velvet. As for hairy fabric, the usual term is velour.

Viscose

Viscose is a manmade textile fiber that mimics the softness of plant fibers, also presenting a silky luster, for which it is also called "artificial silk". It can be used to manufacture fabrics with very different uses ranging from clothes to tires lining.